Messe Dusseldorf, Germany – Thursday 8th May to Wednesday 14th May, 2014

Thank you for visiting Baker Perkins at this year’s Interpack.

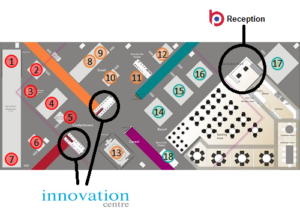

For quick reference, below is a complete list of all process technology we had on display at the show.

Confectionery

1. A ServoForm™ twin-headed depositor featuring a full range of mould technologies for hard candy, lollipops and soft confectionery

2. The NEW Autofeed ingredient weighing and mixing system

3. Demonstration of our NEW integrated automation system for cooking and depositing

4. The NEW Microfilm™ cooker for all types of confectionery syrup

5. The NEW CFA – colour and flavour addition system

6. A NEW Laboratory Depositor

7. A ServoForm™ Lollipop stick feeder and placer

Cereal & Snack

8. An SBX Master™ twin-screw extruder and adjustable cutter

9. A NEW super-cooling barrel extension for production of extruded flakes

10. The NEW Spectrum Colour Changer that allows on-the-run colour changes with no waste

11. A full range of extrusion dies, including:

• A plate die for standard products

• An insert die for diverse product ranges

• A 16-stream co-extrusion die

• An extrusion sheeting die

12. A CoEx Master™ Pillow Crimper with multi-product crimping rolls for co-extruded products

13. The NEW Cook Master™ rotary cereal cooker with centre-shaft steam injection

Biscuit

14. A TruClean™ Rotary Cutter for precise and reliable cutting of crackers and snacks

15. A TruClean™ Gauge Roll: radically redesigned for hygiene and accurate weight control

16. A TruClean™ Wirecut: accurate weight control and hygienic design

17. Our unique High Speed Mixer for all types of biscuits, cookies and crackers

18. A selection of rolls and dies – expertly designed and carefully manufactured for accuracy and durability

Innovation Centre

Our Cereal, Snack and Confectionery Innovation Centres comprised of two separate display stands with a wide range of both new and traditional products in open bowls for inspection. This year, we located these samples closer to the relevant equipment to make a more direct connection between the end product and the Baker Perkins’ process technology used to create them.

Many of Baker Perkins’ expert food technologists from our Innovation Centre were also in attendance to discuss product and process ideas and requirements for the duration of the show.

Baker Perkins at Interpack 2014