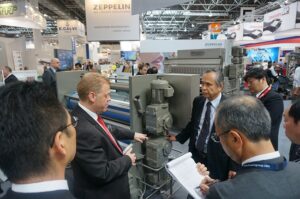

Baker Perkins was at Interpack 2014, at the Messe Düsseldorf, Germany, 8th – 14th May 2014 to demonstrate our confectionery, snack, biscuit and cereal processes.

Innovations that enhance the production process and extend the scope for new product developments in the confectionery, snack, biscuit and cereal sectors were introduced by Baker Perkins at Interpack (Hall 04 / C21). Equipment exhibits linked to an Innovation Centre where visitors co

uld investigate product opportunities for their own business.

Confectionery

For the confectionery industry, upgraded monitoring and control technology means that the entire production line, from ingredient mixing to depositor discharge, is now fully integra

ted and automated.

Additional sensors and actuators in conjunction with

the latest hardware and software help to reduce set up times and improve efficiency. Operators can control the entire line from a single HMI that includes full process visualisation, recipe management, calibration and alarm handling.

Developments that enhance three key components of the cooking process were also highlighted. Equipment upgrades cover the Autofeed ingredient weighing and mixing system; Microfilm™ cooker; and Colour and Flavour Addition (CFA) system.

Biscuit, Cookie & Cracker

A wirecut machine and a dough mixer which combine maximum flexibility with mi

nimal production costs, were the highlights of Baker Perkins’ exhibits for the biscuit industry.

The latest Baker Perkins TruClean™ wirecut machine for soft dough cookies, plus plain and filled bars, was at Interpack for the first time. The result of radical innovation in Baker Perkins’ approach to hygienic design, every aspect of this machine has been reworked to offer more thorough cleaning, more quickly, with easy maintenance.

Food service manufacturers in Europe have invested recently in frozen dough

wirecut machines from Baker Perkins, the leading supplier of equipme

nt in North America where soft dough cookies baked at the point of sale are available in a multitude of retail outlets.

The full Baker Perkins range, meeting output needs from craft to plant-scale bakeries, is now being introduced around the world, coinciding with the development of an innovative concept offering superior levels of performance, choice and hygiene.

HS (High-Speed) multi-purpose mixers handle every type of biscuit, cookie and cracker dough. They feature a unique, shaftless mixer blade ensuring efficient dispersion and rapid dough development, cleaner discharge, the elimination of blade fatigue and cracking, and improved hygiene.

Snacks

The widening array of extruded snacks achieved by creative die technology, and

a new technique allowing product colour changes ‘on the run’, was the focus of Baker Perkins’ presentation for the extruded snack industry.

The range of dies on show at Interpack produces snacks ranging from the standard to the exotic. There is a clear trend towards more complex products, to provide differentiation in a crowded market, and a new development on show is a co-extrusion die with 16 streams for high output production – 12 streams was the previous maximum.

The co-extrusion die produces continuous cereal tubes filled with a savoury paste or cream. The tubes can be formed into a variety of snack formats including mini, bite-size or hand-held pieces in pillow, stick, bar or wafer shapes.

The colour change system enables changeover between variations of an ext

ruded snack to be made ‘on the run’: for example, matching the colour of vegetable-flavoured snacks such as carrot, beetroot or tomato.

Cereal

For the breakfast cereal sector, Interpack marked the launch of the new Cook Master range of batch cookers. The classic Baker Perkins machine is recognised as the market leader in high-quality breakfast cereal cooking for high performance lines. It has no centre shaft, and steam is injected through the side walls. This is now joined by a new cooker with a through-shaft design for customers who prefer

this process option.

Both units provide controlled steam cooking of wh

ole or milled grains, retaining their nutritional benefits while developing the texture and flavour required. Part of the Baker Perkins Cereal Master TX™ range of expandabl

e lines, these high-output batch cookers deliver the highest levels of quality, consistency and efficiency with low operating and maintenance costs.